You’ll notice at the sewing stores that most of the thread is polyester, along with some representation from cotton and rayon. There won’t be much nylon, and the nylon will often be labeled as upholstery thread or some similar non-clothing type. Why is this?

You can read a little about nylon and polyester below, or skip directly to the comparative section that makes it clear why nylon is an uncommon choice for fabric thread, especially clothing.

Nylon

Both nylon and polyester are thermoplastics, which means they are plastics which can be melted and reformed. Nylon was discovered about the same time as polyester by DuPont, but was pursued more heavily in the early 1930s and the turn to polyester occurred later in the decade. There are many types of nylon today (e,g. Nylon 6/6, 6, 510, 1/6, 11, 12), but the most common is the original nylon 6/6 (a.k.a 6,6 or 66), and that’s what’s in most nylon fabrics and threads.

As we’ll see in the tables below, nylon is: strong, abrasion resistant, stretchy, relatively soft, water absorbent, UV damageable, low heat resistance, hard to dye, not very colorfast. These properties make nylon more suitable to practical purposes such as mechanical parts, stretchable thread, and backpack construction. It’s thus less suitable for rich coloring, long term outdoor exposure, sweaty sportswear.

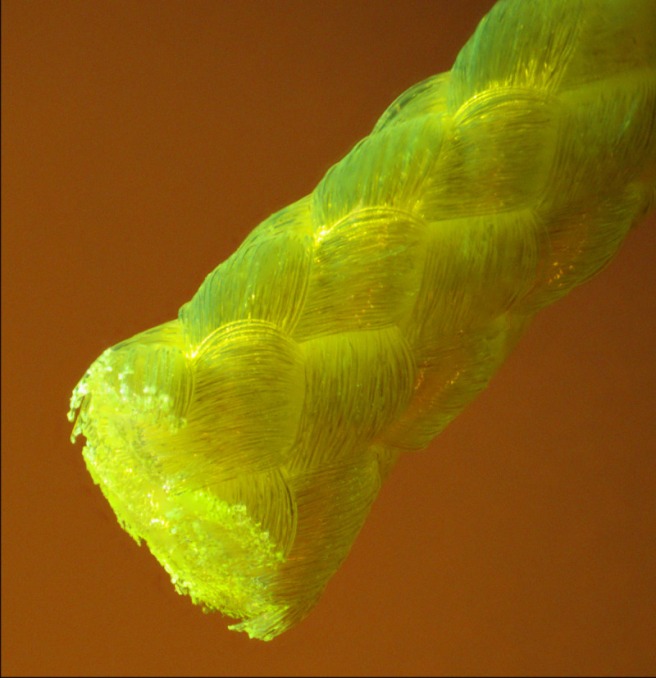

Nylon will often be found in “bonded” form. This means that the individual strands are melted or glued together to make a thread that acts more like a single large strand. Such a thread resists fraying and has a stiffer feel. It may also be more shiny and synthetic looking, though the surface could be softened. You can tell bonded thread by cutting it and twisting the end in your fingers, in which case non-bonded thread will fray. Polyester thread can be bonded as well, but it’s less common.

Typical uses of nylon include high quality carpeting (due to abrasion resistance, stiffness, stain resistance, and strength), backpacks and similar (due to strength and abrasion resistance), upholstery (strength and abrasion resistance), etc. It’s stronger by weight than polyester and so is used in flyweight hiking tents, despite disadvantages otherwise.

There’s one nylon sewing thread that you will commonly find: woolly (a.k.a. stretch or bulky) nylon for overlocking (serging). This is because it provide a soft stretchy matte edge which looks more stylish than a hard shiny thread, while being more resistant to wear.

Polyester

Polyester is a thermoplastic like nylon and was developed in the 1930s as well. While nylon is a material with a wider range or practical uses outside of fabrics, polyester is particularly well suited to use in fabrics and threads. It’s the best all-around thread because it beats alternatives such as nylon, cotton, rayon, Kevlar, and others in many ways. Most significantly, it’s fairly strong, dyes well, retains color, resists UV damage, has a little stretch, runs through sewing machines well, dries quickly. We go into the details of how it compares to nylon, cotton, and rayon below, and will list some weaknesses relative to the others.

While polyester typically looks a little plastic-like and shiny, spun polyester is a type that has a matte look that appears more like cotton but with the strengths of polyester.

Polyester is used in may places beyond clothes, such as carpet, awnings, flags and banners, curtains, luggage, sportswear, tents, book bags, hammocks, and book binding.

Let’s start with how nylon and polyester are similar; then we’ll go into the differences.

Nylon/polyester similarities

Nylon and polyester have more in common to each other than to alternatives.

| Property | Nylon/Polyester | Cotton, rayon, wool |

|---|---|---|

| Source | Both are thermoplastics. | Based on plant or animal materials. |

| Cost | Nominally similar cost as polyester. Special grades of nylon may cost more. | Cotton and rayon are more expensive than polyester, and wool much more so. |

| Maintenance | While polyester stains easier than nylon, cotton permanently stains very easily. | Oils, stains, acids, and even salt water are particularly damaging to cotton. |

| Strength | Lighter, stronger, more durable. | Not as strong or durable. |

| Wrinkles | Wrinkle-resistant. | Wrinkles easily, develops permanent wrinkles. |

| Toughness | Nylon is tougher than polyester, but both are much tougher than organic threads. | Fairly fragile in comparison. |

| Heat / breathability | Polyester breathes more than nylon, but cotton, wool, rayon breathe much more easily in comparison. | Cotton and wool in particular breathe easily when dry. |

| Water | Nylon holds more water than polyester, but cotton and wool hold far more water than either. | Cotton in particular can get heavily soaked. |

| Mildew | More resistant to mold and mildew. | Cotton mildews very easily. |

| Chemicals | Good resistance to acids, bases, bleach and solvents. | Poor resistance to acids and bleach. |

| Allergenics | Not typically allergenic on their own. | May be allergenic for some. |

| Flammability | Much lower melting temperature than cotton and wool. | Higher heat resistance. |

Differences

While nylon and polyester have many high level similarities, there are key differences between them which dictate their roles – in particular polyester’s greater role in fabrics.

| Property | Nylon | Polyester |

|---|---|---|

| Invention | Invented by DuPont in 1935 | Invented by International General Electric in 1928 |

| Composition | Is a form of thermoplastic based on polyamide, produced from petroleum compounds. | Is a form of thermoplastic based on polyethylene terephthalate, produced from petroleum compounds. |

| Types | Nylon comes in various types often by numbers: 6/6, 6, 510, 1/6, 11, 12, pebax, etc. Nylon thread is typically Nylon 6/6. | Polyester comes in two types: PET (polyethylene terephthalate) and UPR (unsaturated polyester). Polyester thread is typically PET. |

| Structure |  (nylon 66) (nylon 66) |  (PET) (PET) |

| Uses | Wide range of industrial and commercial uses. Used in the stockings, tights, raincoats, and swimwear. Carpets, drapes, bedding, lightweight tents. Gears, materials, parachutes, etc. | Limited industrial and commercial use. Used in more clothing than nylon and is also used in carpets, drapes, bedding, conventional tents. |

| Dye | Harder to dye, fewer color options. | Easily dyed, rich color options. |

| Color | Fades quickly and doesn’t hold dye well. | Holds color and does not fade quickly. |

| Stretch | Stretches ~20-50% before breaking, depending on the type. | Stretches 15-20% before breaking. |

| UV | Worse natural UV resistance; breaks down faster unless treated. | Good natural UV resistance. |

| Feel | Naturally softer to touch. Can be felt by running fingers over a spool. | Naturally rougher to touch. More artificial. |

| Strength | Generally higher strength, but depends on the nylon type and material. | Generally lower strength, but it’s complicated. |

| Toughness | Higher resistance to abrasion. | Cut and worn down more easily. |

| Water | Absorbs more water, materials sag. Absorbs 4.0% water. Expands 3.5% when wet, which is a lot. | More naturally water repellent. Resistance increases with rising thread count. Absorbs 0.4% water. Expands less than 0.5% when wet. |

| Wicking | Slower drying, retains moisture. | Faster drying. Better for sports wear. |

| Shrinking | Shrinking: polyester changes size less between wet/dry. | polyester changes size less between wet/dry. |

| Heat / breathability | Retains more heat for a given thread weave/density, breathes less easily. | Breathes better for a given thread weave/density. |

| Longevity | Doesn’t retain it’s shape over time as well. Worse if exposed to UV light (e.g. outdoors). | Retains its shape longer. |

| Flammability | Lower melting and burning temperatures. More susceptible to yellowing at high temperatures. | Higher melting and burning temperature. Retains color better under high temperatures. |

| Static | Generates static electricity more. | Doesn’t generate static electricity easily. |

| Maintenance | Easier to clean; doesn’t stain as much, including with oils. Exceptions are acids and oxidizers (e.g. hydrogen peroxide) | Harder to clean, and stains can be permanent. |

| Recycling | Nylon is hard to recycle. It’s expensive and resource intensive and is only done with pre-consumer materials. | Polyester is easy and efficient to recycle, and can be done with post-consumer materials, including dreaded water bottles. |

Links

- https://en.wikipedia.org/wiki/Nylon

- https://en.m.wikipedia.org/wiki/Nylon_66

- https://www.sciencedirect.com/topics/chemistry/nylon-6

- https://en.wikipedia.org/wiki/Polyester

- https://www.sciencedirect.com/book/9781845692988/polyesters-and-polyamides

- https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=Nylon-Thread-Information

- https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=polyester-Thread-Information

- https://www.jsrz.com/bonded_thread.html

- https://www.sewingpartsonline.com/blog/ultimate-thread-reference-guide/

- https://www.ipsaglobal.net/en/products/high-tenacity-nylon-6-nylon-66.html

- https://www.servicethread.com/blog/materials-science-for-industrial-threads-and-yarns-polyester-and-nylon

- https://www.smarthomesforliving.com/nylon-vs-polyester-carpets/

- https://blog.tortugabackpacks.com/nylon-vs-polyester/

If you have an observation regarding these thread types or feel there’s a mistake, let me know. I found multiple mistakes in third party reporting of this kind of information while researching this, including at some commercial sites. For example one commercial site reported nylon as identical stretch to polyester, most likely because they copied/pasted and didn’t update it.